OIL & GAS HOSE LEADER

OIL & GAS HOSE LEADER

Technical Details of Fracking Hose

Temperature: ﹣29℃~121℃

Inner tube: It is made of UHMW-PE film combined with synthetic rubber

Reinforcement: 6 layers of high strength spiral steel wires

Outer cover: Abrasion and weather resistant synthetic rubber

High pressure frac hose has high pressure and good stability, There are no hidden risks.

The Advantages of the High Pressure Frac Hose

Ø Actively dissipates fluid energy inherently reducing vibration and system stress

Ø Protective outer coating provides long-lasting life of high-pressure hosing

Ø Eliminate costly iron replacements and recertification with specifically designed ID to withstand harsh frac environments

Ø Reduce rig-up and rig-down time with quick and safe hammer unions, hubbed, or flanged connections

Ø Reduced number of connection points eliminating the need for multiple iron configurations

Ø Higher flow rates versus conventional iron

Ø Available with integral end fittings captive within the hose body construction and end-of-life wear indication

Ø In-line swivel available for end connections to prevent torque transfer on makeup

Ø Compact and easily transportable design

Ø High pressure frac hose has high pressure and good stability, There are no hidden risks.

What types of frac hose and what are their applications?

Frac hose is available in different types for various applications, it mainly includes below applications:

Ø High-Pressure Frac Hose: This type of frac hose features high pressure and high-performance abrasion resistance, it works best for conveying fracturing fluid from the blender to the frac pumps in fracturing wellsite.

Ø Suction and delivery hose: This hose is for fluid transfer operations such as hydrocarbon fuels and mineral oils in tank trucks and other industrial fluids.

Ø Suction and discharge hose: This type of hose is used for petroleum-based products transfer.

How to repair high pressure fracking hose?

Improper selection of the frac hoses and the fittings may cause serious damage or injuries in the wellsite frac applications to your crews.

You need also note that the frac hoses are also subject to degrade over time and need appropriate routine inspection and maintenance.

In order to increase the frac hose service life and reduce downtime, it is quite necessary to discuss some criteria questions with your frac hose manufacturer to get the right product. They are mainly:

· Size:

o What inside diameter of frac hose is required?

o What’s the required outer diameter?

o How long is required of a frac hose?

o Any specific requirement on the overall length including fittings?

· Temperature

o What’s the temperature of the product being conveyed?

o What temperature will the external cover be subject to?

· Application

o Where will this frac hose be used?

o How will it be installed or handled?

o Will the hose be subject to any dragging, oils/chemicals, etc?

o Is it a critical, permanent application?

· Material

o What’s the material being conveyed through the hose?

o If it is a chemical, identify the concentration

o If it is a material, is it wet or dry?

o What size are the particles?

o Are they sharp or abrasive?

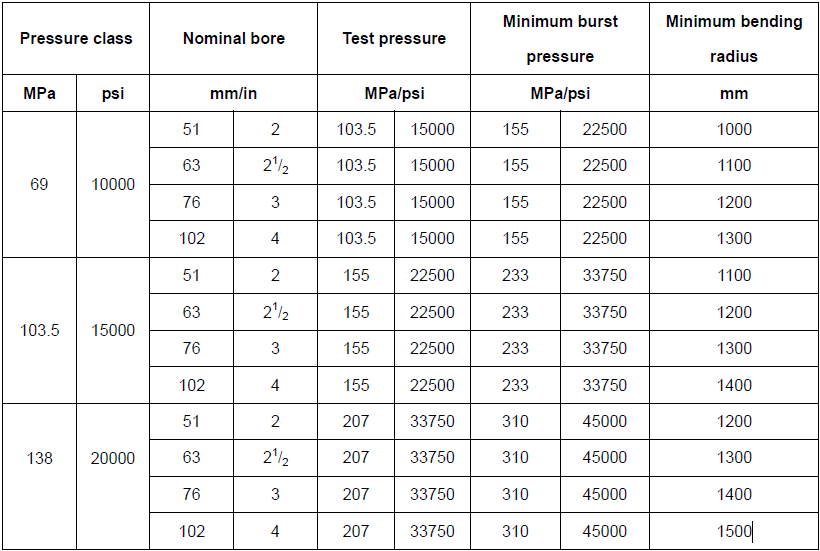

· Pressure

o What’s the maximum working pressure?

o Are there any pressure surges?

· Fittings

o What kind of fitting is required?

· Delivery

o When is the frac Hose required?