OIL & GAS HOSE LEADER

OIL & GAS HOSE LEADER

Rotary Decoking Hose

|

Product Description |

5,000psi W.P. – 10,000 psi Test-12,500 psi Minimum Burst-Grade D

Certification/Standards:

API Spec 7K--ISO 14693

Recommended For:

Coke is one of the by-products used in oil refining. It is stored in silos until it can be loaded into railroad cars for shipment. The coke hardens after being placed in the silos. To unload the coke from the silos, a decoking hose is attached to a drill stem which travels down the silo using warm, high-pressure water to wash the loosened coke from the silo.

Tube:

Modified Nitrile rubber. 3/16” thick, Black. Specially compounded for handling abrasion and corrosion.

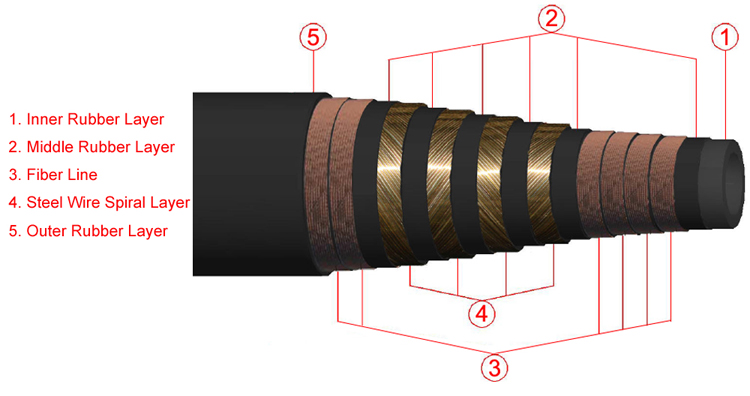

Reinforcement: Multiple layers of textile fabric and steel cable, with one layer middle rubber placed between cable layers.

Cover:

Modified Nitrile. Black. Specially designed Ultra abrasion cover is resistant to abrasion, corrosion, cutting, gouging, oil and weather.

Couplings:

Swaged couplings. API standard flanges or equivalent of your choice.

Temperature:

-4℉ to +180℉ (-20℃ to +82℃) continuous service.

Options:

Accessories such as safety clamps, hose lift eyes and stainless steel armor are available upon request.

Test:

Each hose is tested at 10000psi or 15000psi for 15 minutes. Pressure test graph, test certificate and letter of conformance are issued for each hose.

Specification

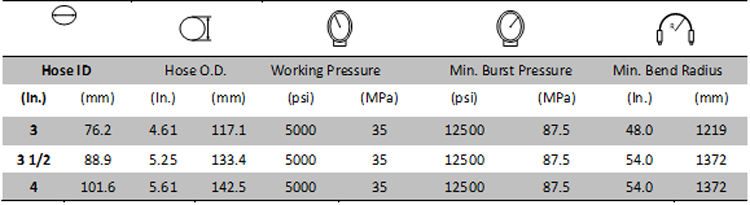

5,000psi W.P. – 10,000 psi Test-12,500 psi Minimum Burst-Grade D

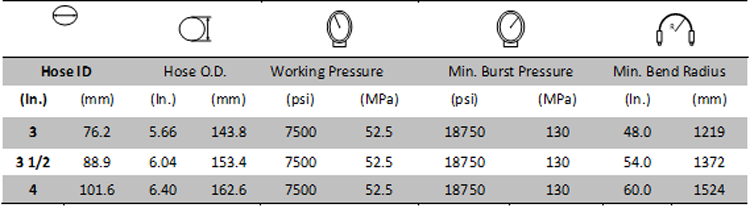

7,500psi W.P. – 15,000 psi Test-18,750 psi Minimum Burst-Grade E

|

Production |

Raw Material:

Rubber materials LG NBR rubber from South Korea.

BELKTA steel wire with high tensile strength 2750MPa from Belgium.

Good quality materials make our Cementing Hose is steady performance, good decentrality and excellent oil resistance.

Factory Workshop:

• SEJIN MACHINE from Korea.

Suspension difference<70 MM, and the international standard is 120 MM.

• Mitsubishi electric control braiding machine.

High accuracy data collection, real-time braiding angle monitoring and correction.

Laboratory:

Strong quality control team, advanced laboratory.

Before the mass production, test each batch of raw material.

After the production, test each hose to guarantee a 100% qualification.

Each hose tested at 2 times of working pressure.

We do everything possible to supply good quality goods for our customer.

|

Packaging |

Special packing is available according to customers’ requirements.

|

Certifications |

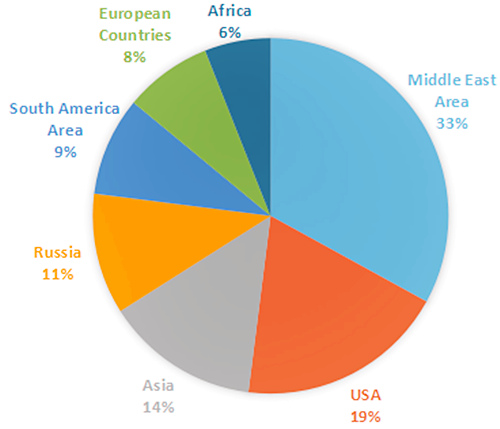

| Market & Exports |

We have clients in more than 40 countries. Such as the USA, Mexico, Brazil, Argentina, Russia, Malaysia, Singapore, Indonesia, India, Germany, Britain, Holland, Kuwait, Saudi Arabia, Iran, the UAE, etc.

| Why Choose Us |

1). ADVANCED PRODUCTION EQUIPMENT

2). ISO 14000 / ISO 9000 / QUALITY CERTIFICATE

3). STRICT QUALITY CONTROL, STRONG R&D TEAM

4). ENVIRONMENTAL FRIENDLY WITHOUT POLLUTION

5). 10 YEARS MANUFACTURING EXPERIENCE, STRONG TEAM