OIL & GAS HOSE LEADER

OIL & GAS HOSE LEADER

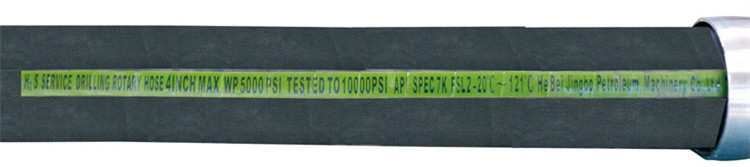

Rotary Vibrator Hose (Kelly Hose) 5000PSI Grade D Sour Service

|

Product Description |

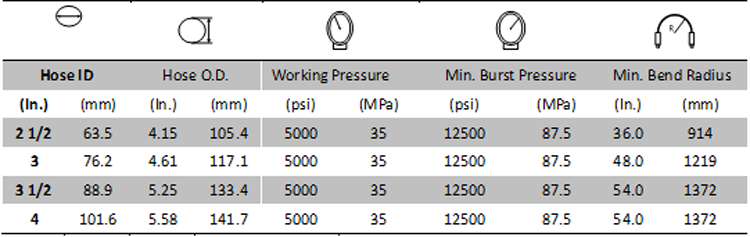

5,000psi W.P. – 10,000 psi Test-12,500 psi Minimum Burst

Certification/Standards:

API Spec 7K-ISO 14693-NACE MR0175

Recommended For:

Flexible connection between standpipe and swivel (Rotary Drilling) or between pump and standpipe (Rotary Vibrator) for pumping mud at extra high pressure in oil drilling and exploration work. Meets the high demands of directional drilling and down linking with negative pressure pulses and elevated temperatures. This hose can also be used as a Motion Compensator hose for stabilization of rotary drilling and pumping equipment against vertical wave action on offshore drill platforms. The Motion Compensator hose is not recommended for phosphate ester fluids.

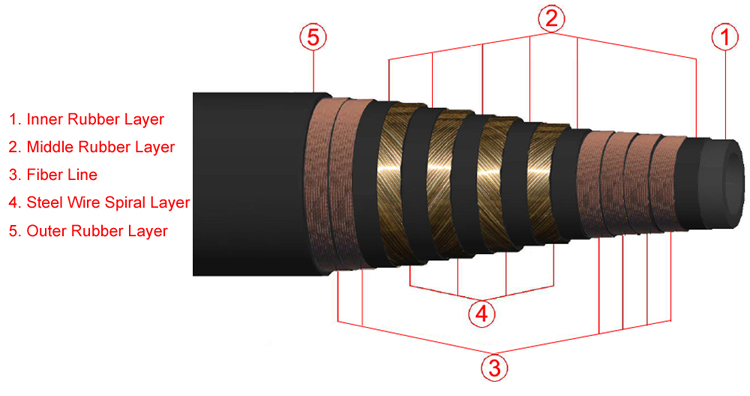

Tube:

HNBR rubber. Black. Resists abrasion, corrosion, oil, and up to 20% H2S.

Reinforcement:

Multiple layers of textile fabric and steel cable, with one layer middle rubber placed between cable layers.

Cover:

Modified Nitrile. Black. Specially designed Ultra abrasion cover is resistant to abrasion, corrosion, cutting, gouging, oil and weather.

Couplings:

Swaged couplings. Full range of couplings are available, such as hammer unions, flanges, camlock, male thread, etc.

Temperature:

-4℉ to +200℉ (-20℃ to +93℃) continuous service.

Options:

Accessories such as safety clamps, hose lift eyes and stainless steel armor are available upon request.

Test:

Each hose is tested at 10000psi for 15 minutes. Pressure test graph, test certificate and letter of conformance are issued for each hose.

Specification

|

Production |

• Germany Lanxess HNBR as raw material.

20% H2S and 80% oil based mud.

Survive the extreme oilfield application requirements and has been no quality complaint for 5 years.

• Stainless steel 316L used as armored jacket.

Factory Workshop:

• SEJIN MACHINE from Korea.

Suspension difference<70 MM, and the international standard is 120 MM.

• Mitsubishi electric control braiding machine.

High accuracy data collection, real-time braiding angle monitoring and correction.

Laboratory:

Strong quality control team, advanced laboratory.

Before the mass production, test each batch of raw material.

After the production, test each hose to guarantee a 100% qualification.

Each hose tested at 2 times of working pressure.

We do everything possible to supply good quality goods for our customer.

|

Packaging |

In general, the packing will use woven bag and plastic film.

Special packing is available according to customers’ requirements.

|

Certifications |

|

Market & Exports |

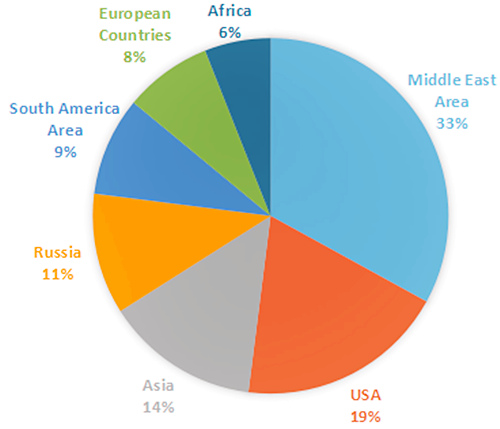

We have clients in more than 40 countries. Such as the USA, Mexico, Brazil, Argentina, Russia, Malaysia, Singapore, Indonesia, India, Germany, Britain, Holland, Kuwait, Saudi Arabia, Iran, the UAE, etc.

|

Why Choose Us |

1). ADVANCED PRODUCTION EQUIPMENT

2). ISO 14000 / ISO 9000 / QUALITY CERTIFICATE

3). STRICT QUALITY CONTROL, STRONG R&D TEAM

4). ENVIRONMENTAL FRIENDLY WITHOUT POLLUTION

5). 10 YEARS MANUFACTURING EXPERIENCE, STRONG TEAM

Please leave message at the bottom for more details, You will get response within 24 hours !