OIL & GAS HOSE LEADER

OIL & GAS HOSE LEADER

Industrial Hose Fuel Discharge Hose 300PSI

|

Product Description |

Recommended For:

Transfer of refined fuels (commercial gasoline, diesel fuel) oils and other petroleum products. Ideal for offshore/onshore transfer applications involving discharge service for diesel oils and other similar petroleum products where an extremely lightweight, flexible hose with a high rated working pressure and a small minimum bend radius is required. Transfer of water, petroleum based fluids, dilute acids, chemicals and abrasive slurries used in oil and gas well stimulation and fracking.

Tube:

black, smooth, NBR rubber

Reinforcement:

high tensile textile plies

Cover:

black, smooth rubber,

resistant to abrasion, heat, oil, ozone and weather. fabric impression

Temperature Range:

-40℉ to +212℉ (-40℃ to +100℃)

Design Factor:

3:1

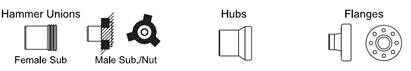

Couplings:

Full range of couplings are available, such as hammer unions, flanges, camlock, male thread, etc.

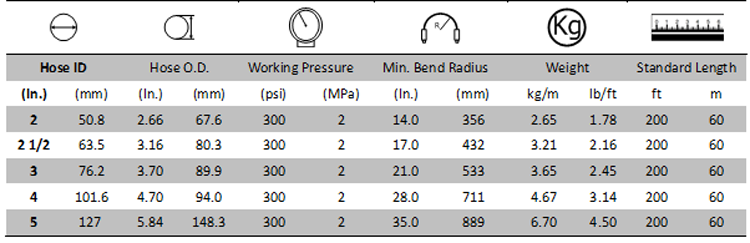

Specification

Standard : ABS approval

Product Show:

|

Production |

LANXESS NBR rubber from GERMANY ,this rubber has the

best quality in the world.

BELKTA steel

wire with high tensile strength2750Mpa from Belgium.

Factory Workshop:

• Spiral Machine is 100%

Servo electronics control from Japan engineer

team’s master work.

The advantage of the machine is high length control accuracy with tolerance <0.001.

• High strength inner

rubber.

Laboratory:

Strong quality control team, advanced laboratory.

Before the mass production, test each batch of raw material.

After the production, test each hose to guarantee a 100% qualification.

Each hose tested at 2 times of working pressure.

We do everything possible to supply good quality goods for our customer.

|

Packaging |

In general, the packing will use woven bag and plastic film.

Special packing is available according to customers’ requirements.

|

Why Choose Us |

2). ISO 14000 / ISO 9000 / QUALITY CERTIFICATE

3). STRICT QUALITY CONTROL, STRONG R&D TEAM

4). ENVIRONMENTAL FRIENDLY WITHOUT POLLUTION

5). 10 YEARS MANUFACTURING EXPERIENCE, STRONG TEAM