OIL & GAS HOSE LEADER

OIL & GAS HOSE LEADER

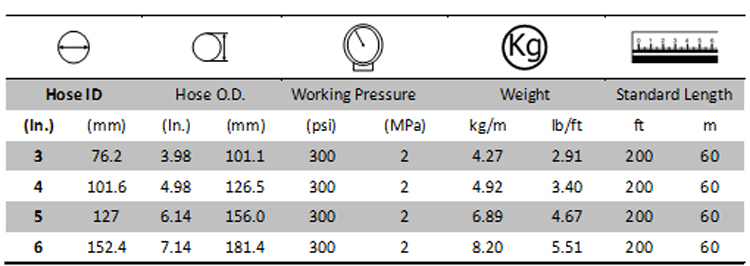

Industrial Hose Bulk Material Discharge Hose 300PSI

|

Product Description |

Recommended For:

Transfer of abrasive materials such as barite and cement from a supply Ship to an offshore drilling rig or platform; and for transfer applications on offshore or onshore drilling rigs or platforms. The natural rubber tube is specially compounded to conduct electricity and made with extra thickness to resist abrasion. The heavy duty reinforcement is designed to survive extreme oilfield application requirements. The specially compounded cover material is designed to withstand the harshest environment including abrasion and weathering.

Tube:

black, smooth, conductive rubber, resistant to abrasion

Reinforcement:

high tensile textile plies

Cover:

black, smooth, weather

and abrasion resistant rubber, conductive, fabric impression

Temperature Range:

-40℉ to +158℉ (-40℃ to +70℃)

Design Factor:

3:1

Couplings:

Full range of couplings are available, such as hammer unions, flanges, camlock, male thread, etc.

Specification

Standard : ABS approval

Product Show:

|

Production |

LANXESS NBR rubber from GERMANY ,this rubber has the

best quality in the world.

BELKTA steel

wire with high tensile strength2750Mpa from Belgium.

Factory Workshop:

• Spiral Machine is 100%

Servo electronics control from Japan engineer

team’s master work.

The advantage of the machine is high length control accuracy with tolerance <0.001.

• High strength inner

rubber.

Laboratory:

Strong quality control team, advanced laboratory.

Before the mass production, test each batch of raw material.

After the production, test each hose to guarantee a 100% qualification.

Each hose tested at 2 times of working pressure.

We do everything possible to supply good quality goods for our customer.

|

Packaging |

Special packing is available according to customers’ requirements.

|

Why Choose Us |

2). ISO 14000 / ISO 9000 / QUALITY CERTIFICATE

3). STRICT QUALITY CONTROL, STRONG R&D TEAM

4). ENVIRONMENTAL FRIENDLY WITHOUT POLLUTION

5). 10 YEARS MANUFACTURING EXPERIENCE, STRONG TEAM