OIL & GAS HOSE LEADER

OIL & GAS HOSE LEADER

BOP Hose

|

Product Description |

Certification/Standards:

API Spec 16D--ISO 14693

Recommended For:

Blow-out preventer (BOP) systems requiring high pressure, high temperature and flame resistant control lines certified to API 16D.

Armored hose assemblies with flame resistant cover withstand minimum 1300°F (+700°C) flame temperature at working pressure for 5 minutes without failure.

Tube:

Modified Nitrile. Black.

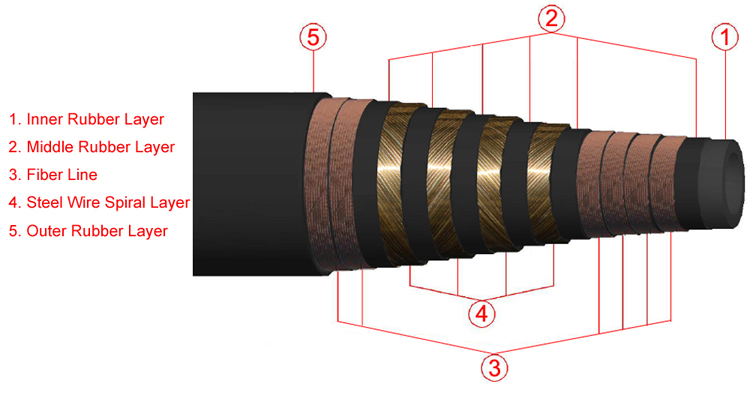

Reinforcement:

Multiple layers of textile fabric and steel cable, with one layer middle rubber placed between cable layers.

Cover:

Fire resistant, rubber cover, stainless steel armored to handle abrasion, corrosion, cutting, gouging, oil and weather.

Couplings:

Crimped couplings with over-ferrule fire protection.

Temperature:

-40°F to +212°F (-40°C to +100°C) continuous service.

Options:

Accessories such as API 16D quick connector, self-sealing union and exterior armor to protect hoses against extreme environmental damage are available upon request.

Test:

Each hose is tested at 10000psi for 15 minutes. Pressure test graph, test certificate and letter of conformance are issued for each hose.

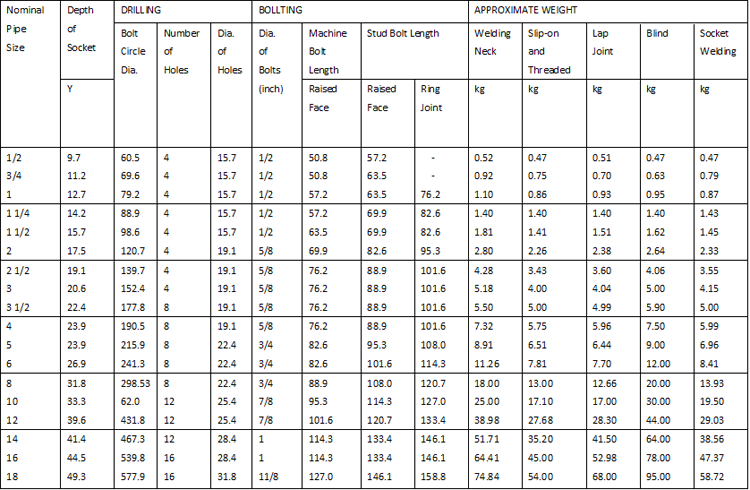

Specification

|

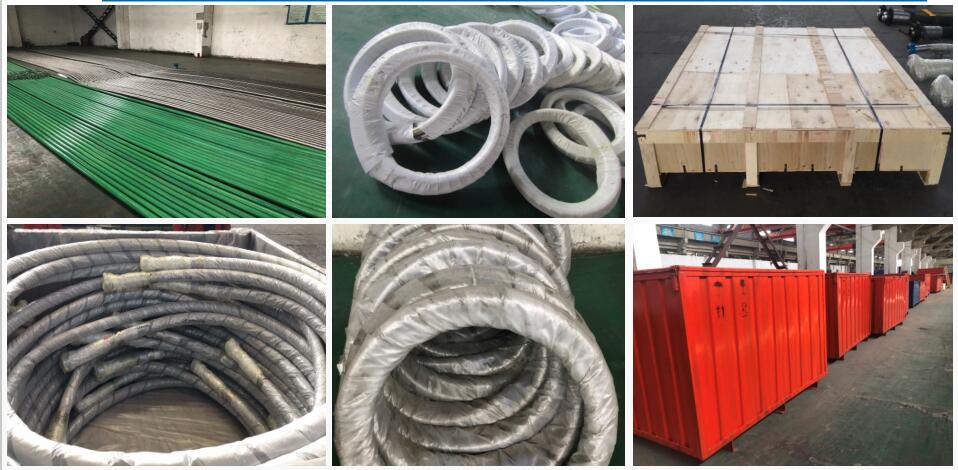

Production |

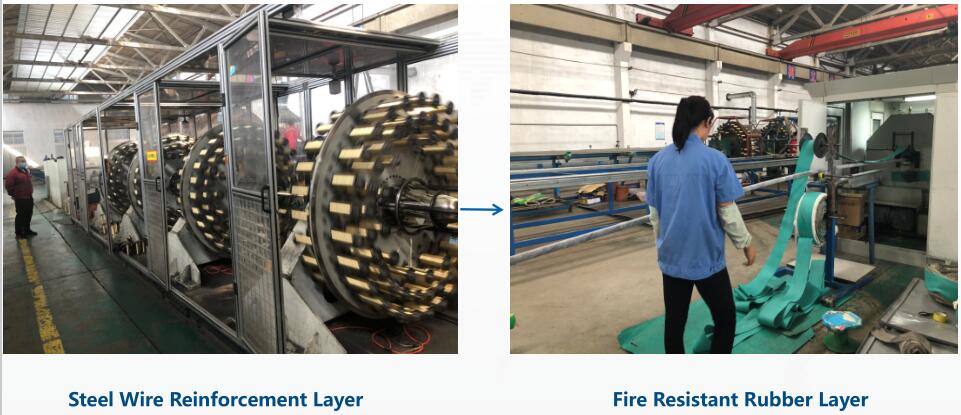

•stainless steel 316 used as armored jacket

Factory Workshop:

• SEJIN MACHINE from Korea.

Suspension difference<70 MM, and the international standard is 120 MM.

• Mitsubishi electric control braiding machine.

High accuracy data collection, real-time braiding angle monitoring and correction.

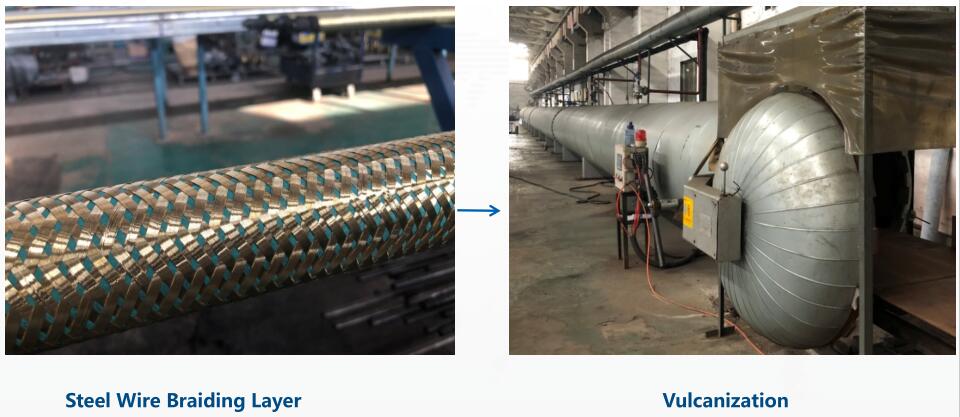

Laboratory:

Strong quality control team, advanced laboratory.

Before the mass production, test each batch of raw material.

After the production, test each hose to guarantee a 100% qualification.

Each hose tested at 2 times of working pressure.

We do everything possible to supply good quality goods for our customer.

| Packaging |

Special packing is available according to customers’ requirements.

| Certifications |

|

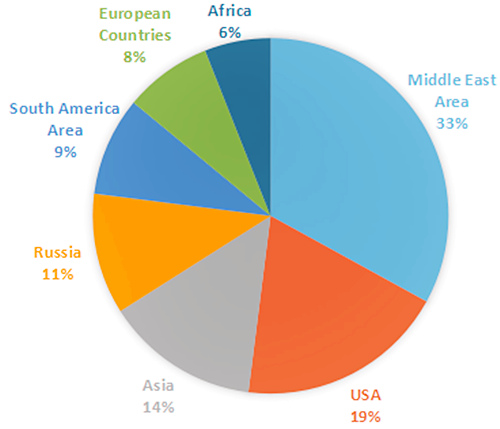

Market & Exports |

| Why Choose Us |

1). ADVANCED PRODUCTION EQUIPMENT

2). ISO 14000 / ISO 9000 / QUALITY CERTIFICATE

3). STRICT QUALITY CONTROL, STRONG R&D TEAM

4). ENVIRONMENTAL FRIENDLY WITHOUT POLLUTION

5). 10 YEARS MANUFACTURING EXPERIENCE, STRONG TEAM